Bintangor Plywood

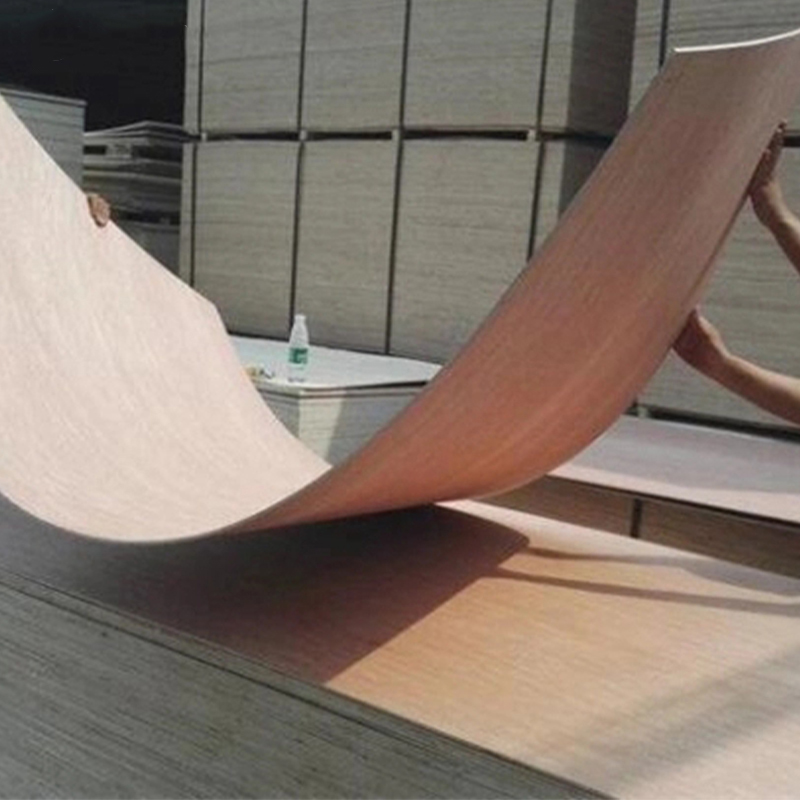

Bintangor Plywood

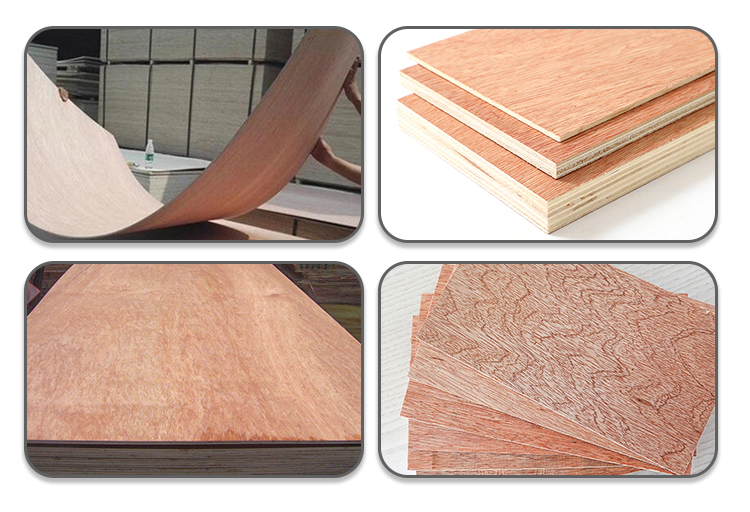

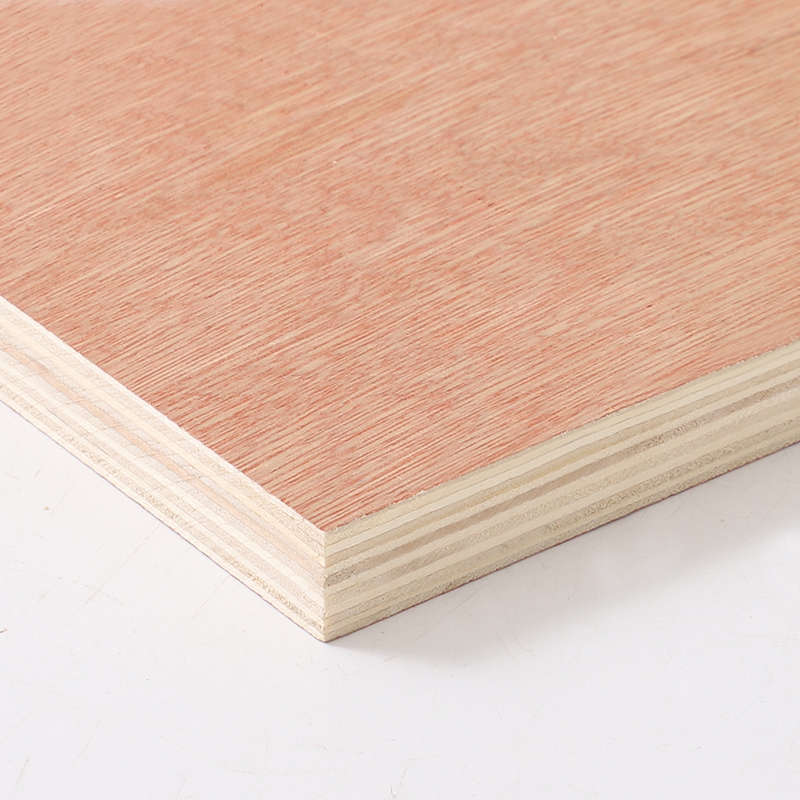

- Product Name:Bintangor PlywoodSize:1200*2440Material:Poplar/Eucalyptus/ Birch/Hardwood Combi/as requestPort:QingDaoGlue:WBP GluePlace of Origin:ShandongMOQ:500 Pieces

- INQUIRY

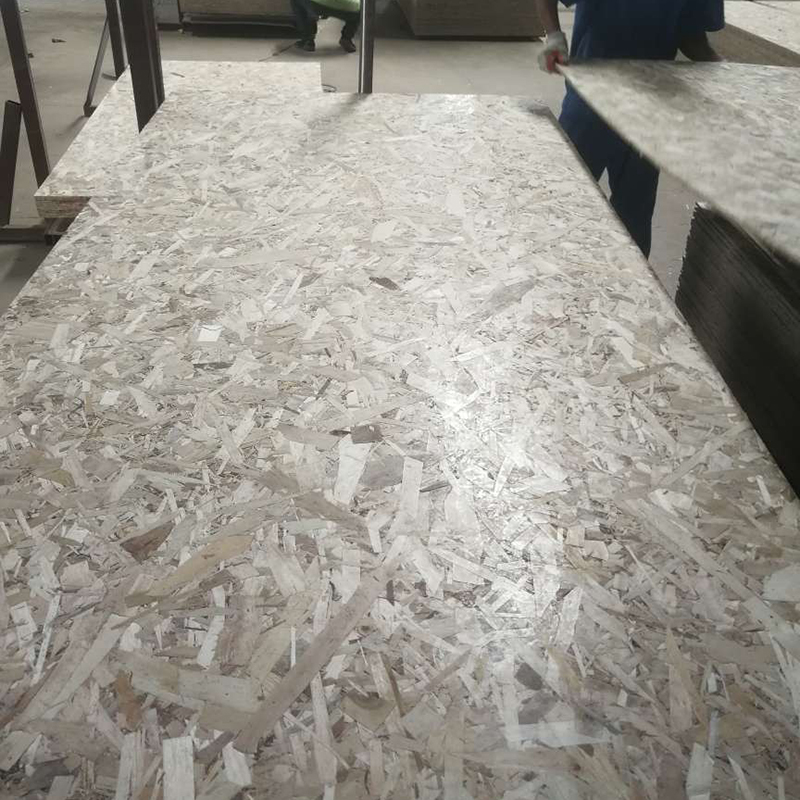

Shandong Aou bintangor plywood production process

1. High-quality full-core middle plate is used, and there is no void in sawing to ensure the strength and toughness of the plate

2. From the core board to the panel, all use armor-free soybean protein adhesives, which are ecologically healthy

3. Layer-by-layer dipping, high temperature and high pressure, the core board and the adhesive are perfectly penetrated and bonded, and the bonding strength is increased by 20%

4. Dry the core board, the moisture content of the board is constant, and it is flat and firm

5. The unique Marari structural core board arrangement, the board is more in line with the mechanical structure

6. Two times of sanding, three times of hot pressing, the surface of the board is smooth and flat

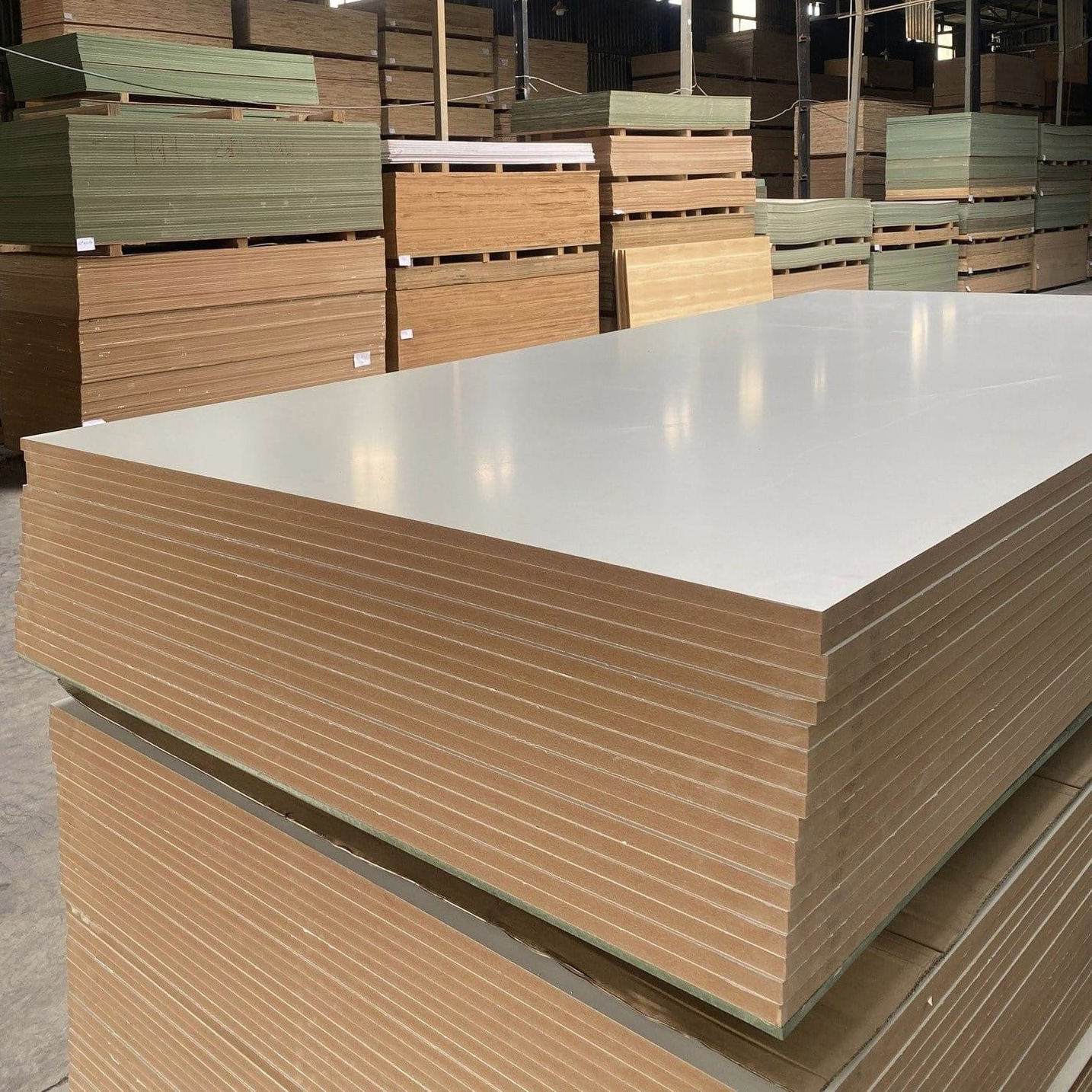

140°C two-time heat-pressed substrate

100℃ veneer

Whether it is the substrate or the surface layer of the decoration, it is perfect enough

Does not open glue, does not break, does not peel

High nail holding property

Cutting edges are smooth and burr-free

PREVIOUS:PeriodNEXT:Period

PREVIOUS:PeriodNEXT:Period

Categories

News

Contact Us

Contact: Plywood

Phone: +8616653921804

Tel: +8616653921804

E-mail: admin@sdaou.com

Add: Zhongxijiang Village, Fangcheng Town, Lanshan District, Linyi City, Shandong Province

admin@sdaou.com

admin@sdaou.com