What Is Marine-Grade Plywood?

Marine-grade plywood is a high-quality, water-resistant plywood specifically designed for use in moist or wet environments. Unlike standard plywood, it is manufactured with waterproof glue and void-free core veneers, making it ideal for applications where exposure to water is frequent or prolonged.

Key Features of Marine-Grade Plywood

Water Resistance: Marine plywood is bonded with waterproof phenolic resin, which prevents delamination even in submerged conditions.

High-Quality Veneers: It uses only solid, knot-free wood veneers that are uniform and dense, eliminating internal gaps that could trap moisture.

Durability: Resistant to rot, warping, and fungal attack, it can last for years even in extreme environments.

Sanded Finish: Marine plywood is usually sanded on both sides for a smooth and consistent surface, ideal for finishing or painting.

Common Uses

Boat Building: The most common use, due to its ability to withstand constant water contact.

Docks and Piers: Excellent for outdoor structures that are exposed to water and weather.

Bathroom and Kitchen Cabinets: Suitable for high-humidity areas inside homes.

Exterior Wall Sheathing: Offers extra protection in damp climates or flood-prone areas.

Marine Plywood vs. Regular Plywood

Marine-grade plywood is often confused with exterior or pressure-treated plywood, but they serve different purposes. Marine plywood contains no chemical treatment but is manufactured to higher standards, making it more stable and stronger in wet conditions. Regular plywood, on the other hand, may delaminate or rot when exposed to moisture over time.

Is Marine Plywood Worth It?

Although marine plywood costs more than standard plywood, its long-term performance in wet environments often makes it the better investment. For construction, marine applications, or moisture-prone projects, it's the trusted choice among professionals.

Keywords: marine-grade plywood, what is marine plywood, waterproof plywood, marine plywood vs regular plywood, uses of marine plywood

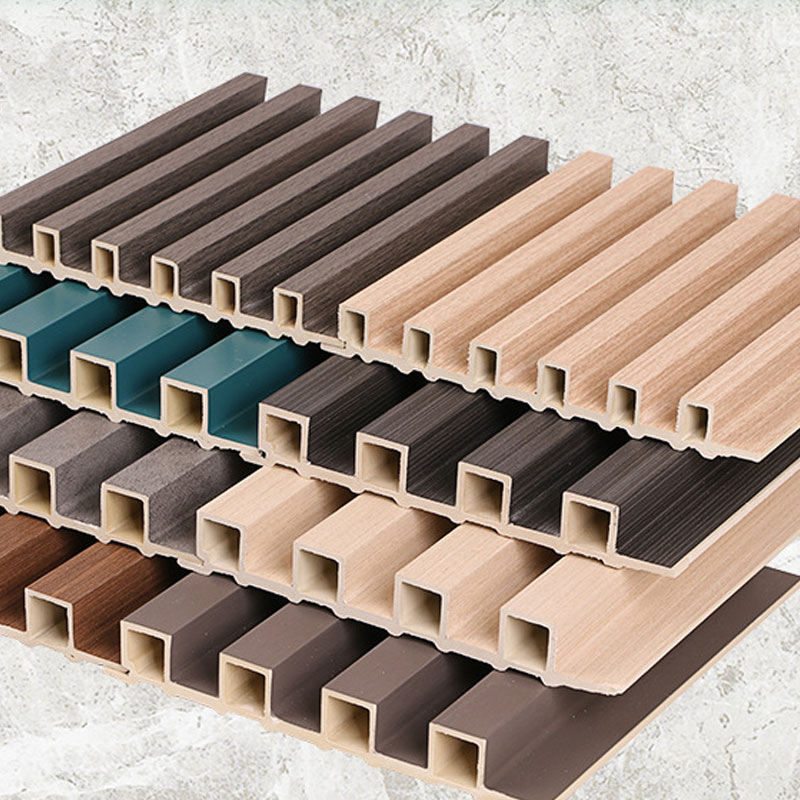

What Material Is WPC?

What Material Is WPC?

What is the average cost of pl

What is the average cost of pl

Okoume Plywood by Aouwood

Okoume Plywood by Aouwood

How Much Does a 4x8 Sheet of P

How Much Does a 4x8 Sheet of P