What are the disadvantages of MDF?

What Are the Disadvantages of MDF (Medium-Density Fiberboard)?

Medium-Density Fiberboard (MDF) is a popular engineered wood product widely used in furniture, cabinetry, and interior decoration. While it offers affordability and a smooth finish, MDF also comes with several disadvantages you should consider before using it.

1. Not Water-Resistant

MDF is highly susceptible to moisture damage. When exposed to water or high humidity, it can swell, warp, or break down, making it unsuitable for outdoor use or damp environments like bathrooms unless treated.

2. Weaker Than Solid Wood or Plywood

MDF lacks the grain structure found in natural wood, so it's not as strong or durable. It can sag under heavy loads and is more prone to damage during installation or use, especially at corners and edges.

3. Difficult to Repair

Once damaged (e.g., chipped or dented), MDF is hard to repair cleanly. Unlike solid wood, it doesn’t take nails or screws as well and may split or crumble when fasteners are removed or replaced.

4. Heavy and Dense

Although it's called "medium density," MDF can be heavier than plywood. This makes handling, transportation, and installation more labor-intensive.

5. Emits Formaldehyde

Standard MDF contains urea-formaldehyde resins, which can release harmful VOCs (volatile organic compounds) over time. Though low-formaldehyde and formaldehyde-free options exist, they may be more expensive.

6. Not Suitable for Fine Carving or Detailed Edges

MDF’s uniform surface is great for painting, but it’s not ideal for intricate cutting or fine molding. Edges can be rough and may require sealing or edge banding.

Conclusion

MDF is a cost-effective, smooth-surfaced material widely used in interiors. However, its moisture sensitivity, weaker structure, and formaldehyde emissions make it less ideal for certain projects. Always weigh these MDF disadvantages against your needs and consider alternatives like plywood, solid wood, or HDF when appropriate.

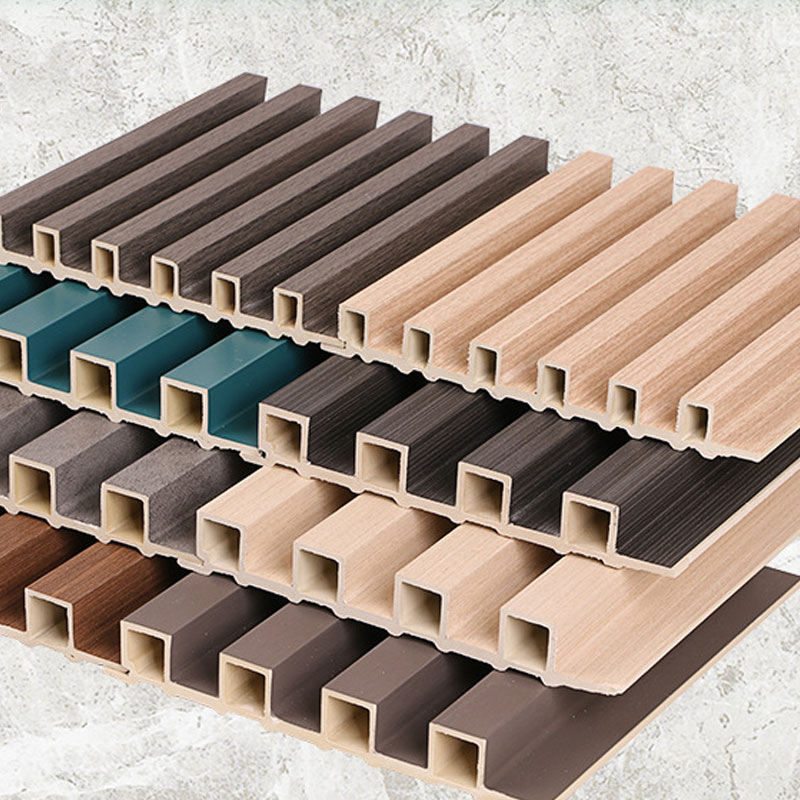

What Material Is WPC?

What Material Is WPC?

What is the average cost of pl

What is the average cost of pl

Okoume Plywood by Aouwood

Okoume Plywood by Aouwood

How Much Does a 4x8 Sheet of P

How Much Does a 4x8 Sheet of P