What are the disadvantages of particleboard?

Particleboard is a low-cost engineered wood product made from wood chips, sawdust, and resin. While it's widely used in budget furniture and cabinetry, it comes with several drawbacks that are important to consider.

1. Poor Moisture Resistance

Particleboard is highly vulnerable to water and humidity. Exposure to moisture causes it to swell, warp, or crumble, making it unsuitable for kitchens, bathrooms, or outdoor use unless it’s specially treated.

2. Low Strength and Durability

Compared to MDF or plywood, particleboard is weaker and more brittle. It doesn't hold nails or screws well and can easily break or sag under heavy loads, especially in shelving or flooring applications.

3. Shorter Lifespan

Furniture made from particleboard tends to have a shorter service life. It’s more prone to chipping, cracking, and edge damage, especially under frequent use or during moving and assembly.

4. Difficult to Repair

Once damaged, particleboard is hard to fix. Unlike solid wood, it doesn’t handle re-drilling or re-fastening well, and damaged areas often can’t be restored to original strength or appearance.

5. Contains Formaldehyde

Standard particleboard uses urea-formaldehyde glue, which may release VOCs (volatile organic compounds) into the air. Although low-emission or CARB/EPA-certified options exist, they may cost more.

6. Rougher Finish & Limited Aesthetics

Unlike MDF, particleboard has a coarser, uneven surface and often needs a veneer or laminate to look attractive. It’s not ideal for painting or detailed finishing.

Conclusion

While particleboard is a budget-friendly material for low-load, indoor furniture, its moisture sensitivity, low durability, and health concerns limit its applications. For projects requiring more strength and longevity, alternatives like MDF, plywood, or solid wood are often better choices.

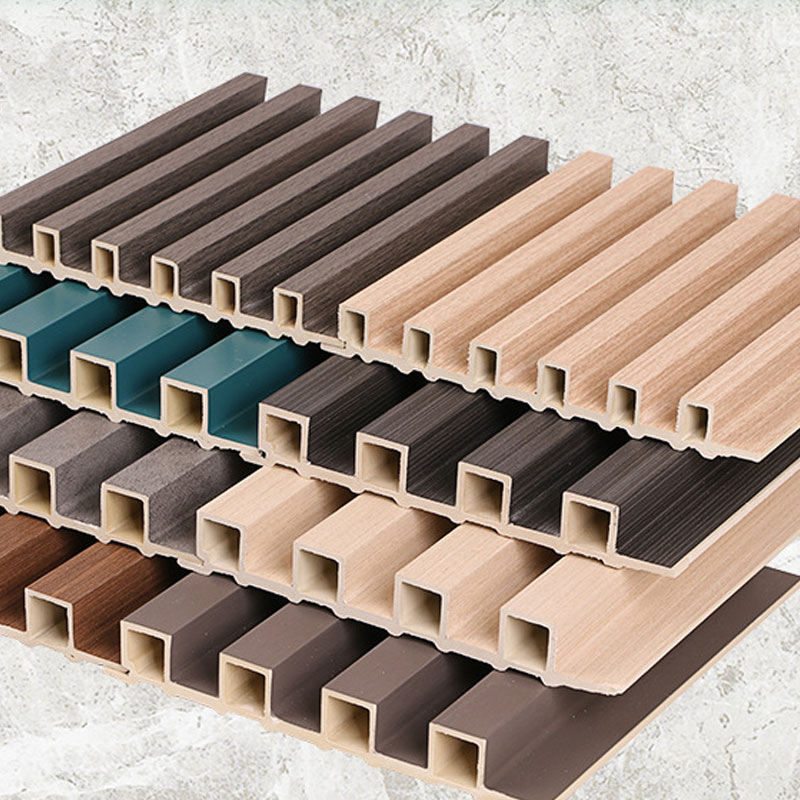

What Material Is WPC?

What Material Is WPC?

What is the average cost of pl

What is the average cost of pl

Okoume Plywood by Aouwood

Okoume Plywood by Aouwood

How Much Does a 4x8 Sheet of P

How Much Does a 4x8 Sheet of P