Can WPC be used for exterior walls?

Wood–plastic composite (WPC) panels can be—and increasingly are—used as exterior cladding or wall siding, but there are some important considerations:

1. Weather Resistance

Moisture: WPC is inherently more water-resistant than solid wood, so it won’t rot or warp.

UV Stability: Over time, UV can cause some fading or chalking. Look for products with UV-stabilizers or factory-applied UV protective coatings.

2. Thermal Expansion & Contraction

WPC expands and contracts with temperature swings more than fiber-cement or metal.

Design tip: Allow for appropriate gaps at joints and install per the manufacturer’s recommended clip or rail system.

3. Mechanical Properties

Strength: Good impact resistance—won’t dent as easily as vinyl.

Weight: Heavier than vinyl, lighter than most stone or fiber-cement, so framing and fixings must be sized accordingly.

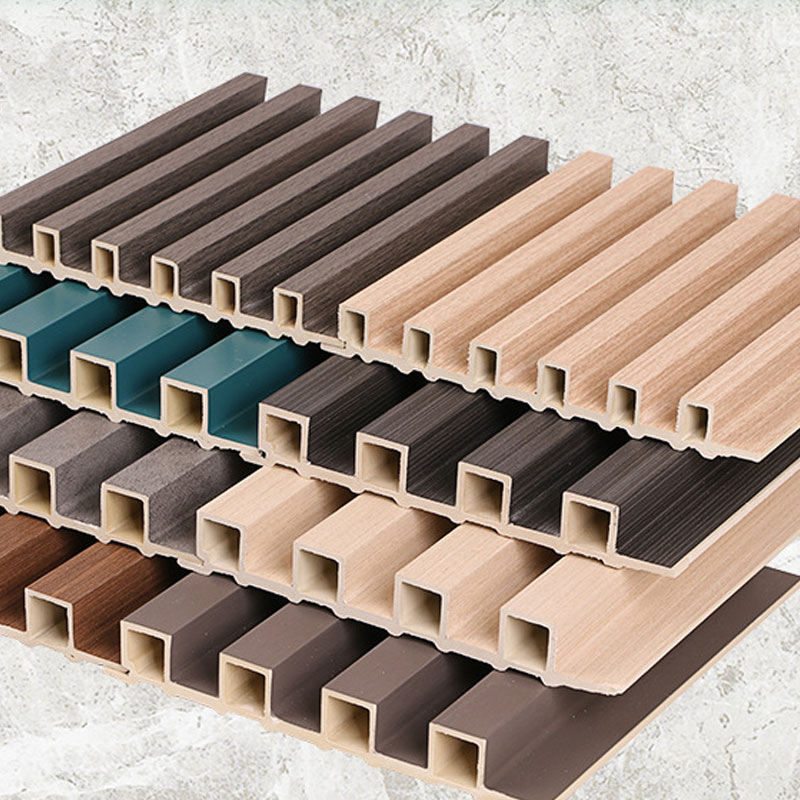

4. Aesthetics & Finishes

Available in wood-grain textures or smooth modern finishes.

Can be painted, but you’ll need to use exterior-grade acrylic paints designed for low-energy surfaces.

5. Fire Performance

Most WPCs are combustible; check for a fire-rated formulation or additional fire-resistant treatment if required by your local building code.

6. Maintenance

Annual cleaning with mild detergent and water.

Inspect fasteners and expansion gaps every couple of years.

Typical Applications

Residential siding

Commercial facades

Accent walls (e.g. under soffits, entryway surrounds)

Outdoor lounges or pavilions

Installation Best Practices

Sub-frame: Mount onto a pressure-treated timber or aluminum rail system.

Ventilation: Create a rainscreen cavity so any moisture that gets behind the panels can drain and evaporate.

Flashing & Sealing: Properly flash window and door openings to keep water out.

Bottom line:

WPC is a perfectly viable option for exterior walls—just be sure to choose a product rated for exterior use, follow installation guidelines carefully, and maintain it periodically.

What Material Is WPC?

What Material Is WPC?

What is the average cost of pl

What is the average cost of pl

Okoume Plywood by Aouwood

Okoume Plywood by Aouwood

How Much Does a 4x8 Sheet of P

How Much Does a 4x8 Sheet of P