Differences Between MDF, MDP, Plywood, and OSB

With growing concerns about sustainability and the carbon footprint of buildings, new construction methods and innovative possibilities for wood usage have rapidly evolved. This renewed interest in wood stems partly from its renewability, though this benefit depends on sustainable harvesting and proper forest management to allow natural regeneration. However, wood's versatility is the primary driver of its widespread adoption. From planks to beams, flooring, and even insulation and soundproofing bricks and panels, wood can be employed at multiple stages of a single project, processed and finished to varying degrees.

In the case of manufacturing furniture, wall coverings, ceilings, and even flooring, the use of wood panels represents an economical and practical way to incorporate timber into buildings. A wide variety of wood panels are available on the market, each employing different manufacturing processes involving fibers, particles, chips, or boards, resulting in specific applications. Next, we highlight the most commonly used wood panels, including their characteristics and primary uses:

MDF (Medium-Density Fiberboard)

MDF panels are made from wood fibers bonded with synthetic resins and compressed under pressure and heat, forming a solid, highly uniform board with excellent finish and durability. Since the fibers are randomly oriented, machines can cut them in any direction, providing a smooth surface. Naturally, the board is not highly water-resistant, but more moisture-resistant, and sometimes even fire-resistant, options are available on the market.

Currently, MDF boards are the most commonly used woodworking material because they are compatible with many different finishes, including simple paint, natural veneers or melamine bonding, and even pattern printing. But they can also be used elsewhere, such as wall and door cladding.

HDF (High-Density Fiberboard) is very similar to MDF, but their manufacturing processes differ. Compressed under higher pressure, these boards are more resilient, support greater weight, and can cover larger expanses.

Particleboard and MDP (Medium Density Particleboard)

Particleboard is made by pressing wood particles (like sawdust and wood dust) with resin and glue. Over time, this material has given way to alternatives like MDF or its newer counterpart, MDP. It can be finished with paint or varnish, but adhesion is often poor due to its rough or uneven surface. Its primary advantage is low cost. Its applications resemble those of MDF, but specific hardware and fasteners are required for satisfactory results.

Similar to particleboard, MDP panels are made from wood particles compressed and heat-pressed with synthetic resin. The difference lies in the distribution: finer particles are deposited on the panel surface, while the thickest particles form the core. This arrangement allows for a smoother finish, better adjustability, and more possibilities for overlay applications. It is not highly moisture-resistant and may have some defects, making the resulting panels widely used in simple furniture production.

Plywood is formed by vertically laminating and heat-pressing overlapping wood veneers. Like cross-laminated timber (CLT), the perpendicular grain orientation in plywood enables the panel to withstand greater pressure.

Plywood serves diverse applications. It can be used for furniture, flooring, ceilings, doors, countertops, and more. It is also compatible with paints and adhesives for natural veneers or melamine finishes.

OSB boards possess a very distinctive aesthetic that is increasingly incorporated into architectural designs. These panels are made from vertically laminated wood chips bonded with resin under high pressure and temperature. They offer excellent mechanical strength and rigidity. Beyond providing good sound insulation, they are internally void-free with no knots or cracks, resulting in a highly uniform surface. They are also eco-friendly and durable, capable of withstanding outdoor exposure and the effects of rain, moisture, wind, and heat. Moreover, these panels are fully recyclable. However, due to their rough surface, laminate products cannot be applied to them.

The primary applications of OSB include walls and ceilings, subfloors for carpet installation, wood flooring, brickwork, cladding and construction sheathing, packaging, and furniture structures.

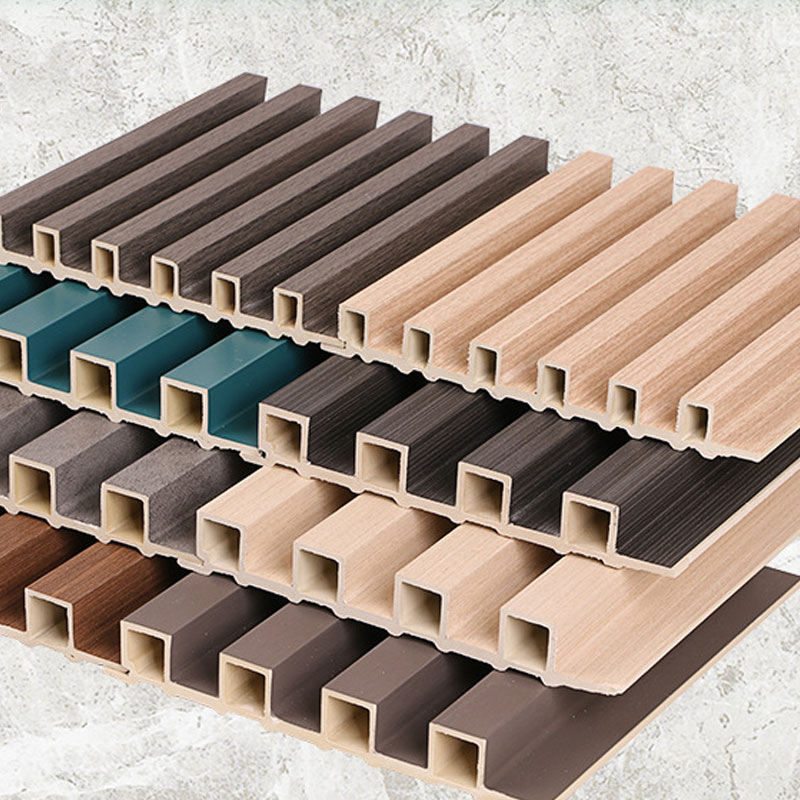

What Material Is WPC?

What Material Is WPC?

What is the average cost of pl

What is the average cost of pl

Okoume Plywood by Aouwood

Okoume Plywood by Aouwood

How Much Does a 4x8 Sheet of P

How Much Does a 4x8 Sheet of P